Advanced Craftsmanship

“One day, our technology will be considered outdated, but our craftsmanship will still be honored.” - Cal Newport Deep Work

Mens et Manus - Mind and Hand, it’s the motto of MIT and one that’s stuck with us from the beginning. It’s a nod to the concept of translating ideas and making things, and in a pre-digital world - by hand and it’s one we care about deeply about at Ministry of Supply.

We believe in the melding of Invention & Convention, combining the time-honored crafts of knitting and sewing with new techniques to unlock products that weren’t possible before and with greater precision. It’s about the way make things.

Advanced Craftsmanship

Ministry of Supply’s advanced craftsmanship is rooted in our manufacturing partners who take pride in their skilled team, advanced machinery and technical know-how. Here are a few ways they bring this to life.

Creating Tools

Every craft has its tools of the trade, and a common practice in woodworking and metal-smithing is the creation of tools and jigs, to hold materials together in a precise manner specific to that product.

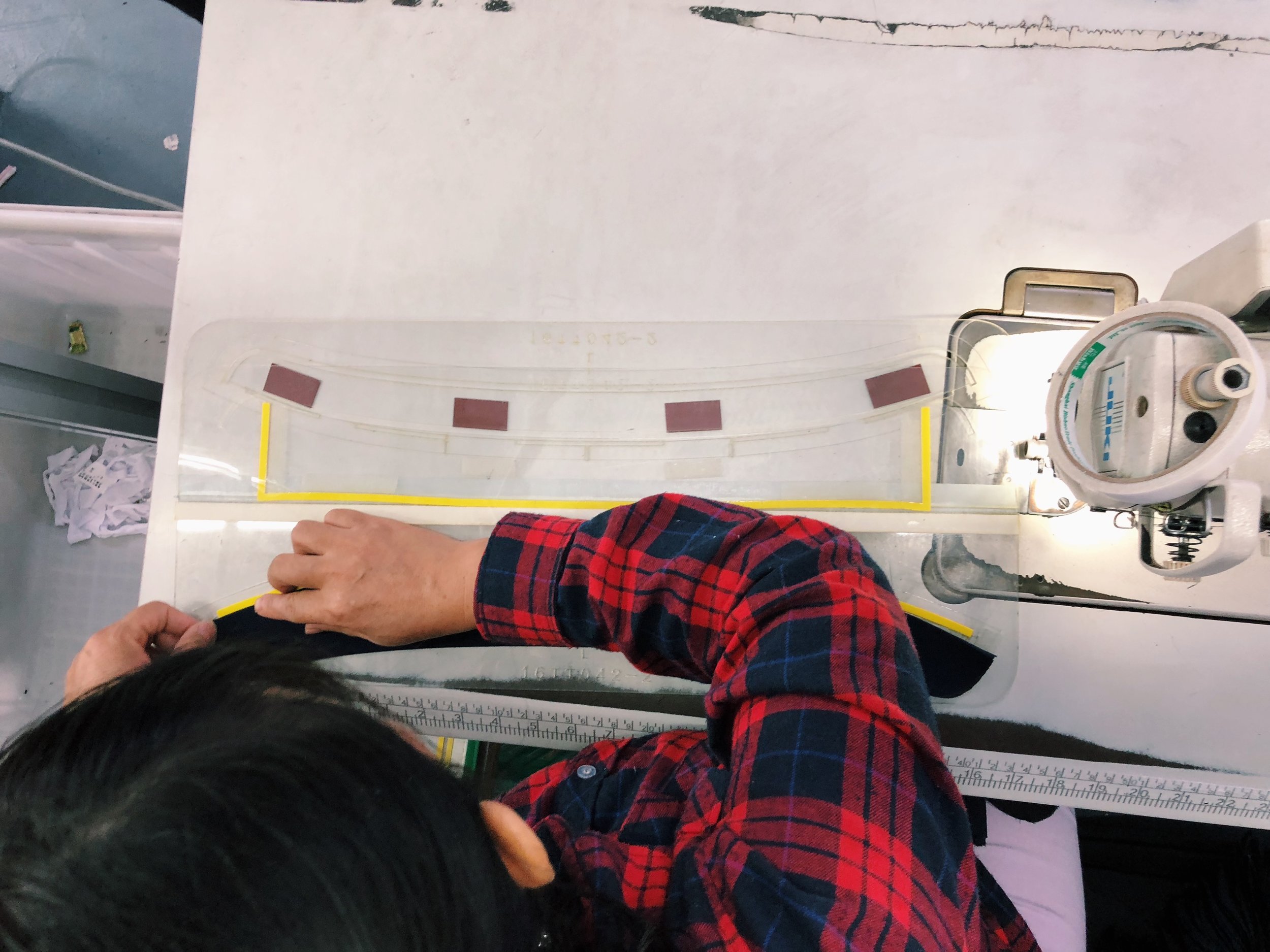

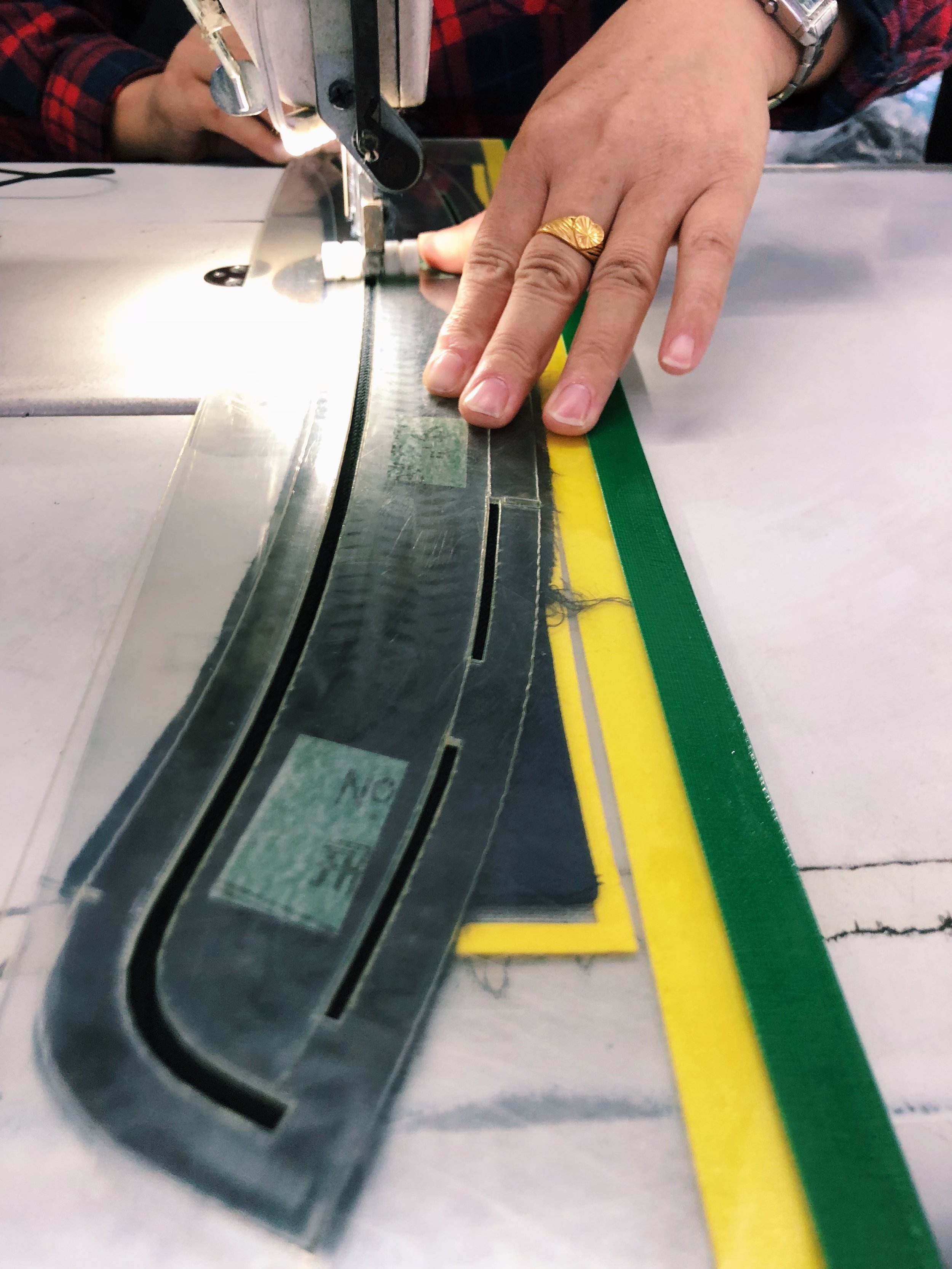

Cutting Templates for Consistency. Creating collars is a challenging process, the precision of the seam work dictates how the collar will curve and lay. A collar contains ten pieces of fabric, interfacing and collar stays - to ensure these are all lined up, we create templates out of plexiglass, that are digitally routed and cut, with adhesive surfaces, registration anchors to ensure all layers are laying on top of each other correct. The template turns floppy fabric, into a stiff sheet, that can then be guided through the sewing machine trough tracks routed into the template. The result is a consistent shape and fit every time.

Co-bots Computer Aided Tools

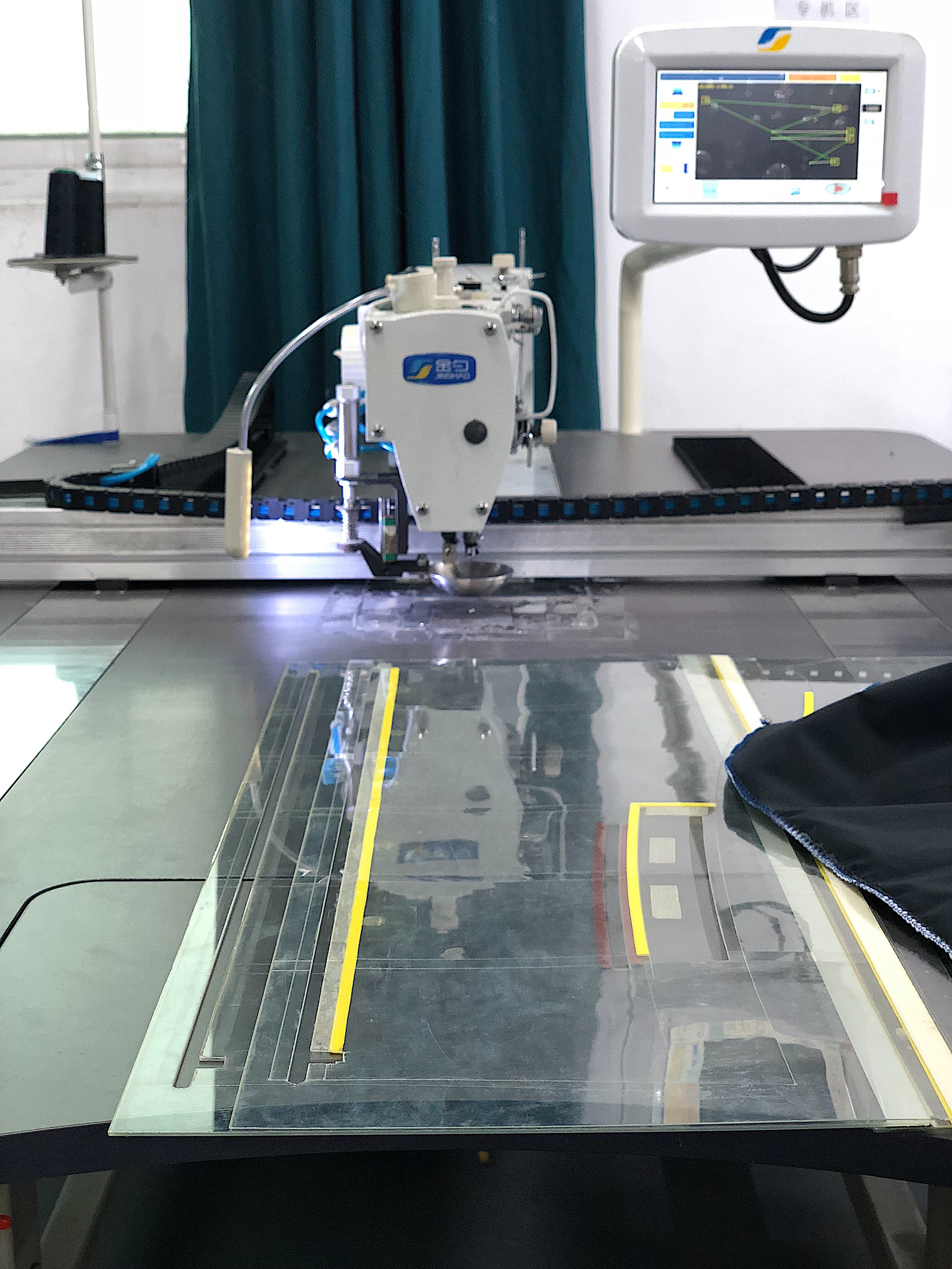

People and computer-aided machinery allows us to create consistent and precise patterns that wouldn’t be possible .

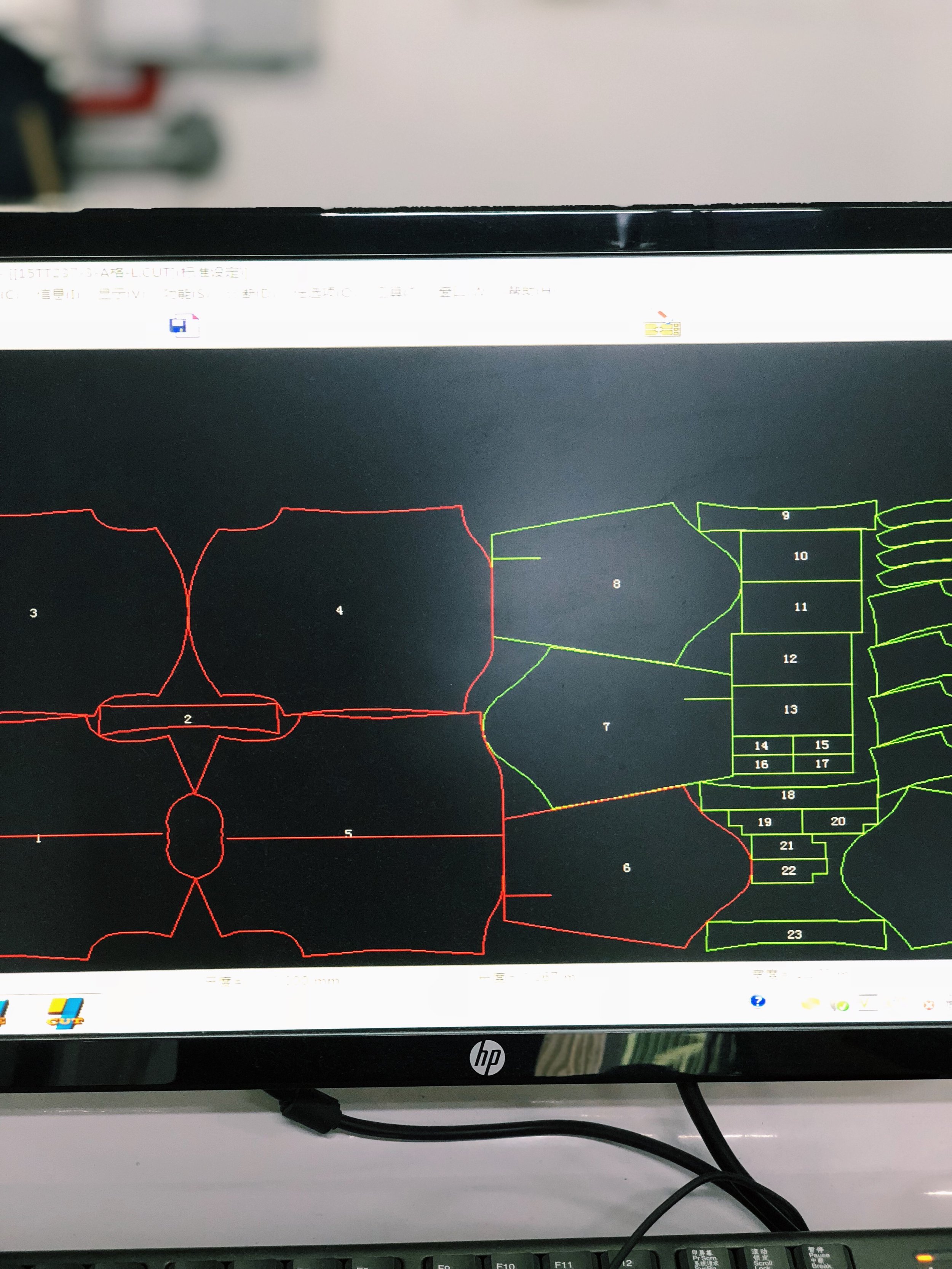

CNC Cutting for Consistent Fit: A consistent fit begins with a consistent cut, while previously layers of fabric were stacked and cut by hand with variance between layers and cuts, this process uses a vacuum to hold the fabric in place and cutting saw cut through the layers. This allows more efficient material cutting as well as the required tolerances are narrower by machine, leading to less material waste, and allows workers to focus on optimizing cutting layout. Used in all of our garments.

Laser Cutting for Precise Ventilation: We use laser cutting in our signature under-arm perforations in the Aero shirt and the speaker-grille style ventilation in the Mercury Jacket, which simultaneously cut and seal the yarn edges. Traditional process would have used embroidered eyelets, which are bulky and are limited to stiffer fabrics.

Computerized Knitting for Complex Structure: Computerized knitting allows complex knit structures to be made consistently. It’s an old manufacturing technique that is part the art of knitting mixed with the science of knit-programming. Used in our Atlas Sweaters and 3D-Print Knit Garments

Computerized Sewing for Intricate Designs: The quilting of our Mercury Jacket

Advanced Joinery

Much of garment manufacturing is about connecting fabric panels together. While single needle stitching remains the most common type, other types such as overlock, and flat lock stitching have unlocked low-profile seams, perfect for next-to-body application.

Thermo Lamination for Low-Profile Seams: Used in our Luxe Touch and Juno where we want elegant, low profiles seams for a light-weight flow fabric and in our Doppler for waterproof seams that don’t require extra layers of seam taping. A layer of glue is heated between two layers of fabric under pressure creating a tight bond.

Ultrasonic Bonding for Elegant Stabilization: Used in our Mercury Jacket, instead of piercing the fabric which would undermine the waterproofness, ultrasonic welding is used, where a vibrating cone causes two layers of fabric to rub against each other and heat up due to friction. This heat causes the layers to fuse together without any glue or stitches.

Skilled Craftsmen

There are people, there are hands behind every product we make. Clothing still is one of the most manually intensive processes.

Sample Room: Every garment starts in a sample room, it’s where initial prototypes are made by the most-skilled sewers so that they can not only make the sample, but think through the best way to construct the garment for quality and manufacturability at scale. It’s part design, part development, part manufacturing - and it’s the heart of our product development.

Needlework: Sewing with consistent seam allowances, and with even, steady speed is an art, but require years of work and knowledge of how different fabrics react. This is important to create consistent tension and seam strength.

Linking: While computerized knitting can create flat panels of fabric, for many of our sweaters hand-linking is done, whereby linkers individually mount each knot on a needle and align it to the stitch from another panel to create a virtually seamless garment. It’s process that requires true skill - while cheaper garments may rely on overlocking - linking results in smooth seam with consistent stretch, particularly in the armhole where it’s felt most.